Полная версия:

Circular economy in action: Regional adaptation of global strategies. The case of Georgia

Real estate in Switzerland plays a significant role in the country’s sustainable economy, with environmental aspects becoming an integral part of property management. Sustainability principles are being actively implemented throughout all stages of a building’s life cycle, from design and construction to operation and renovation. Zurich Invest, one of the leading players in the real estate market, underlines the importance of eco-friendly solutions with a focus on energy efficiency, reduction of CO₂ emissions, and minimization of resource consumption.

One of the main strategies is building and managing buildings that meet the Minergie standards and other environmental certifications. These would reduce the energy consumption of buildings through modern insulation technologies, energy-efficient heating and cooling systems, and integration of RE sources such as solar panels. More than one-third of the global demand for energy and about 40% of the CO2 emissions can be traced to buildings. In Switzerland, buildings produce 26% of greenhouse gas emissions. According to Zurich Invest, 95% of their portfolio in real estate has already been certified according to ecological standards or is under consideration for it; this again attests to the commitment towards sustainable development.

Moreover, special attention is drawn to the renovation of old buildings by substantially enhancing energy efficiency. New projects involve eco-friendly materials to reduce not only carbon footprint but also to maintain a healthy living environment.

Green areas also need to be integrated into the development. Green roofs, urban gardens, and rainwater collection systems not only clean the air but also ease the burden on city infrastructure, adding to climate change adaptation. These measures contribute to the CE by supporting a closed-loop system of resource use.

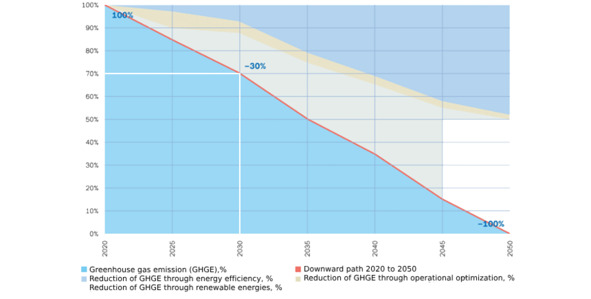

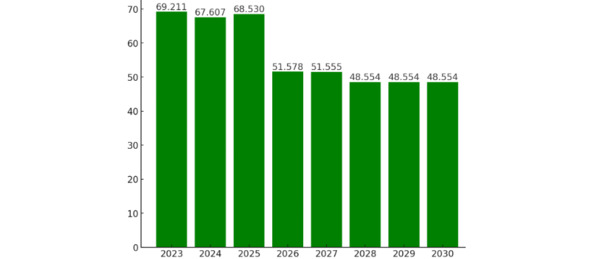

Zurich Invest’s global goal is to achieve climate-neutral real estate construction by 2050 and reduce greenhouse gas emissions by 30% by 2030 (fig.10).

Figure 10. Zurich invest’s strategy for reducing carbon footprint [39]

Thus, Switzerland demonstrates how real estate can become a driver of sustainable development by minimizing environmental impact and improving quality of life. Examples such as Zurich Invest show that environmental approaches in property management not only contribute to environmental protection but also represent economically advantageous solutions, creating value for both owners and society as a whole.

Switzerland is one of the leading countries in the CE, and such success may be attributed to several important factors. First, the achievements of Switzerland are driven by its very developed recycling infrastructure. That country invests heavily in cutting-edge technologies and infrastructure projects for the purpose of reusing materials after recycling them as effectively as possible. The scope of waste recycling in Switzerland is rather broad, as it covers construction debris and even components of old electronic equipment. This full-cycle approach reduces reliance on imported raw materials and reinforces the local economy.

The success of a CE in Switzerland finds its foundation in a profound tradition of public awareness and environmental responsibility: the Swiss are very aware of and involved in all aspects of waste sorting and recycling, which significantly increases their recycling rate and reduces their landfills. This perspective on sustainable consumption cuts through every stratum of society, from young schoolchildren to adults, and this guarantees the good implementation of every governmental environmental policy.

Besides, Switzerland has an extensive government support system through financial and tax incentives that encourage corporate activity for sustainability. Government-subsidized programs for encouraging innovation in the environmental field are given significant support so that companies can adopt advanced technologies and methods of material recycling. Such subsidies include companies that specialize in plastic recycling or firms that invest in ecological construction technologies.

The interplay of effective recycling infrastructure, a highly environmentally conscious populace, government support, and business enterprise thus turns Switzerland into a global example of how to transition towards a CE.

1.2.3. Germany

Germany, as the representative of the EU countries with developed economy, is among the forerunners of implementing CE principles. During the late 20th century, this very concept started to actively evolve due to the first legal laws aimed at waste minimization and efficient resource use. A key step in this process was the Packaging Waste Act of 1991, which required producers to take responsibility for the collection and recycling of packaging materials [40]. This approach formed the basis for the EPR principle. In 1996, the Closed Loop Waste Management and Disposal Act was passed, giving a legal form to the concept of the CE and setting priorities: avoidance of waste, re-use, recycling, and disposal as the very last option.

Today, Germany boasts probably one of the most demanding ecological regulatory systems in the world. The revised Closed Loop Waste Act, which started its implementation in 2012, set more stringent demands on sorting and recycling for all kinds of waste, organic and industrial alike. In 2019, the Packaging Act was passed, expanding producer obligations and setting minimum recycling standards, such as 63% for plastics in 2023. These initiatives are part of the National Sustainable Development Strategy, which is included in the EU’s CE Action Plan [41]. Starting in 2025, new rules for waste separation will be introduced in Germany. People who put foreign objects in organic waste containers will now be fined up to €2,500.

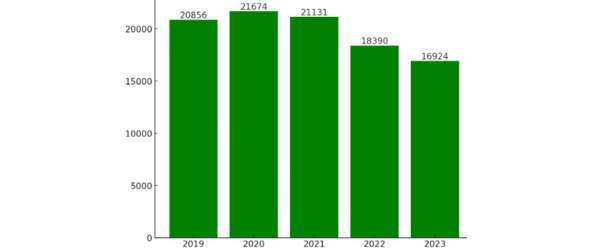

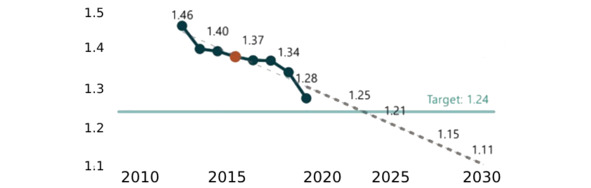

The CE covers almost all the most important sectors of the German economy. More than 67% of household waste is recycled in the waste recycling sector, which is one of the highest rates in the EU. Industrial enterprises, like BASF, introduce closed carbon cycle technologies, reprocessing by-products of production to obtain new products. In the last years, due to such actions, CO2 emissions have been decreasing (fig. 11).

In the energy sector, Germany is actively developing biogas plants that process organic waste. In 2023, RE sources accounted for 55% of the electric power produced in Germany, of which 8,4% came from biomass, including biogas. In the construction industry, more than 90% of construction waste is recycled or reused, and new building materials are designed with consideration for their subsequent recycling.

Figure 11. CO2 emissions by BASF, metric tons [42]

The automotive industry, particularly BMW, actively uses recycled materials such as aluminum and plastic in the production of new vehicles. Starting in 2025, the Neue Klasse models will feature plastic trim parts, 30% of the raw material for which will come from marine plastic waste [43]. The carbon footprint of these components will be approximately 25% lower than that of corresponding components made from conventional plastics. BMW also uses recycled fishing nets to make fabrics for ceiling panels and floor mats in the BMW i3, BMW iX, and other models. The BMW Group has set an overall goal to increase the share of secondary materials in thermoplastics used in new cars, from approximately 20% at present to an average of 40% by 2030.

Germany has achieved significant success in the development of the CE through a comprehensive approach that combines strict environmental laws, innovation, and a high level of environmental awareness among its population [44]. The country aims to achieve carbon neutrality by 2045, with intermediate targets for reducing greenhouse gas emissions: a 65% reduction by 2030 and an 88% reduction by 2040 compared to 1990 levels. As mentioned, one of the most important aspects was the early legislative framework regarding Closed Loop Waste Management that established a waste management hierarchy, emphasizing prevention, recycling, and reuse. Germany is actively implementing technologies in sectors such as waste recycling, energy, and industry. High waste separation was able to occur with modern infrastructures such as recycling plants and waste separation systems. Innovation supports the effective re-creation of materials from waste, such as plastic wastes recycled for new material use and organic waste used for the production of biogas. Additionally, environmental education and public awareness encourage active citizen participation in implementing the principles of the CE, making Germany a leader in this field.

1.2.4. Netherlands

The Netherlands is considered one of the forerunners in the world regarding the CE due to its ambitious strategy and integration of sustainable principles into key sectors of the economy. In 2016, the country adopted the Circular Netherlands by 2050 program with the aim of full transition to a CE and excluding the use of primary fossil, metallurgical, and mineral resources [45]. A second, intermediate goal is to reduce the consumption of these resources by 50% by 2030. This strategy relies on close collaboration between the government, business, academia, and citizens, allowing for the development of inclusive and scalable solutions.

In the Netherlands, the National Program for CE 2023—2030 was adopted. It encompasses a broad area, including reduction in primary resources, material recycling, prolonging the useful life of products, and substitution of secondary and bio-based materials. One of the critical components of the program pertains to improving recycling processes to make use of resources efficiently, especially within priority sectors like consumer goods, building materials, plastics, and agriculture. The program also includes international cooperation to make the transition equitable, such as on environmental standards and improving labor conditions along the value chain [46]. It also sets out a package of incentivizing and regulatory measures for reaching the objectives on reducing CO₂ emissions and increasing the resilience of the Dutch economy. According to reports, a number of challenges are said to face the national CE program for 2023—2030, including limited budgetary resources (fig.12).

Figure 12. Financing of the CE in the Netherlands, thousand euros

Among the major drivers of CE development in the country is high population density and lack of natural resources-a factor that makes efficient material use vitally important. Waste recycling systems are actively being developed in the country, and among the priorities are organic, construction, and plastic waste. This has been made possible through a strictly regulated waste segregation system and the implementation of innovative recycling technologies [47]. For example, construction waste recycling allows the production of high-quality secondary materials, which are used in road construction and the housing sector.

The Netherlands is also at the forefront of plastic recycling. The country is part of the Plastic Pact NL initiative, under which the goal is to have 100% of the packaging made of recyclable plastic by 2025 [48]. Further, innovative projects like chemical recycling plants are making complicated types of plastics into raw materials for the manufacture of new materials. These technologies substantially reduce dependence on primary plastics and reduce the carbon footprint of the industry.

Agriculture also contributes importantly to the CE of the Netherlands. Recycling organic waste, like manure and agricultural residues, into biogas and compost, which are used as fuel and fertilizers, respectively. Furthermore, initiatives on vertical farming and aquaponics methods are underway, limiting the use of water and soil while generating a more sustainable food value chain.

Dutch industry is embracing circular models, like the recycling of metal waste. Several eco-industrial parks have been created in the country’s largest industrial and logistics center, the port of Rotterdam, in which one company’s waste serves as a resource for another. This helps minimize the amount of waste generated along with lowering CO₂ emissions. One successful example includes a carbon recycling program that transforms carbon emissions into chemical products and construction materials.

The Netherlands is also heavily investing in education and research initiatives. Universities and research centers such as Delft University of Technology play a key role in developing new technologies and training specialists in sustainable development. Support programs for startups and innovative companies help implement circular solutions in small and medium-sized enterprises. For instance, the Amsterdam-based platform Circle Economy provides companies with tools to transition to closed-loop production models.

International cooperation is a key factor in the success of the Netherlands. The country actively participates in European and global initiatives for the CE, thus enabling it to attract investment and share best practices with other countries. That is why the Netherlands has been called a “living laboratory” of the CE: it can scale up innovative solutions and integrate them into the real economy.

Despite active promotion of the CE, the introduction of RE in the Netherlands has been burdened with a number of serious problems for quite a long time. The first important problem concerns slow sector development in comparison with many other EU countries. In 2015, the proportion of RE in the country’s overall energy balance equaled just 5,8%, the lowest index among all the EU nations. Whereas, in 2022, the Netherlands got only 15% of its consumption of energy from renewable sources [49]. The reason for this lag is explained by the heavy dependence on natural gas from the large Groningen field and the absence of sufficient government incentives.

Key barriers included constrained investments in wind and solar energy, lack of infrastructure to integrate RE, and high technology costs at an early stage of their deployment. Besides, the densely populated country with limited land made it complicated to construct large RE generation facilities. The low level of RE consumption can also be partly explained by the generally flat and often below-water terrain that results in a limited availability of hydroelectric resources.

In the long run, the Netherlands wants to be a fully CE: waste is to be transformed into resources, with as little environmental impact as possible, while the economy remains competitive and sustainable. These measures will not only improve the state of the environment but also reinforce the country’s position as one of the leaders in innovation and sustainable development worldwide.

1.3. Australia

The Australian experience in transitioning to a CE is unique and interesting, underpinned by the geographical position, natural resources, and socio-economic aspects. Australia is the biggest island continent in the world, with immense natural resource deposits, and at the same time faces challenges associated with their rational use. Being far away from key global markets, having partial infrastructural development in some parts, and having high environmental risks related to climate change, the transition to the CE is not just an ecological but also an economic necessity [50].

Australia is also particularly well-placed to achieve a CE transition due to its sound research base, technological capabilities, and government support. In 2021, the Australian government adopted the National Waste Policy Action Plan, which has set ambitious goals in terms of reduction of the waste produced by the commercial sector (fig.13).

Figure 13. The amount of solid household waste produced by the commercial sector, tons per capita [51]

Natural resources are of great importance to the Australian economy. Australia is one of the major exporters of metals, coal, and gas. However, overexploitation of these resources has created several problems, such as resource depletion and increased carbon emissions. In this context, the CE is a strategy that could ensure long-term economic sustainability by minimizing waste, recycling materials, and reusing raw materials.

Initiatives towards waste reduction include the elimination of single-use plastics. Because Australia has imposed strict regulations concerning the manufacturing and consumption of various single-use plastic products since 2022, this initiative will eventually reduce the volume of plastics landfilled substantially, triggering further development in the capacity to recycle plastic wastes, including chemical recycling facilities and the development of biodegradable materials by the year 2024.

Furthermore, Australia is actively implementing programs of organic waste recycling. It has introduced composting systems at both the family and community levels that help diminish methane emissions to the atmosphere from landfills. Until 2024, more than 50% of organic waste will be recycled in Australia, placing the country among the leaders of developed economies on this indicator [52].

An interesting aspect involves the mining industry in applying the principles of the CE. Companies dealing with extraction, including but not limited to iron, lithium, and rare earth elements, started installing waste recycling systems into their production cycles. For instance, Lynas Rare Earths involved in extracting and processing rare earth metals implemented the use of reagents’ recycling in their technological cycles, which decreases water usage and reduces industrial waste significantly. They also have projects on ecosystem restoration in mined areas.

Despite these successes, Australia is also experiencing various challenges in the implementation of a CE. Among these is the disparate waste recycling infrastructure between urban and rural areas. Many remote regions, like deserts and thinly populated areas, are devoid of recycling facilities and logistic solutions that would provide opportunities for material reuse, which results in increasing the costs of waste transportation.

Technological challenges also play a significant role. For example, recycling complex materials like lithium-ion batteries and composite plastics requires substantial investments in research and development. Furthermore, recycling technologies remain expensive, which slows their large-scale implementation.

The social aspect of the transition to a CE needs attention, too. Though Australians are increasingly aware of the importance of recycling and material reuse, in some parts of the country this is still inadequate. This is especially true in rural areas, where cultural and economic barriers often stand in the way of active participation in recycling initiatives.

Investments also play an important role in the implementation of the CE in Australia. The government invested in the year 2023 approximately AUD 1,5 billion for projects of waste recycling, creation of closed supply chains, and the development of technologies of secondary usage [53]. These investments will be channeled into a sustainable infrastructure that would see Australia achieve its CE goals by 2030. Examples include the building of plastic waste recycling plants in the states of Victoria and New South Wales, which created hundreds of new jobs.

In 2024, nine districts in South-East Australia pledged to divert at least 95% of their waste to energy recovery plants and not to landfills over the coming 25 years. These are in response to the forecasted increase in landfills in this region by 40% by 2046. Waste would be used to generate energy instead of landfilling it, thereby reducing the amount of greenhouse gas emissions. For each ton of waste recycled, 0.8 tons of emissions are saved. This will reduce 270,000 tons of emissions every year, which equals taking 50,000 cars off the road. More than 500 temporary jobs will be created during the construction of the waste-to-energy plant and around 450 permanent jobs when it becomes operational [54].

Thus, Australia’s practice of transitioning towards the CE shows how one can use the specific geographical, social, and economic features of the region to turn to the models of sustainable development. The country, with government support, active investments, and business involvement, is moving confidently towards achieving the results of its CE, although many challenges have yet to be overcome. This experience can serve as a model for other developed economies that strive to create a more sustainable and resource-efficient development model.

1.4. Canada

Canada, with its rich natural resources and developed industry, is well aware of the need to switch to a CE in order to achieve sustainable development and increase competitiveness. In this respect, the major drivers for the transition are environmental problems linked to increased volumes of waste and their negative impacts on the environment [55]. The CE contributes to minimizing pollution and optimizing resource use. The second significant point refers to economic efficiency, which will be promoted by using secondary materials and waste recycling to decrease raw material costs and dependency on imports. Such aspects of social importance as creation of new jobs in recycling and ecological manufacturing contribute to the improvement of quality of life and development of local communities.

The country of Canada is carrying out the transition to a CE through the establishment of recycling infrastructure, introducing production technologies using minimal waste, and raising public awareness. That is, the construction of new recycling facilities, especially those involved in processing plastics, metals, and organic waste, is to be supported, along with the encouragement of companies to make goods with longer lifespans and with potential for reuse. Key sectors where such changes are taking place include industrial manufacturing, which is introducing closed-loop material cycles, construction that actively uses recycled materials, and agriculture with the application of composting for organic waste reuse.

Another unique feature of the Canadian way is the emphasis on energy-efficient homes. Because of the northern climate, Canadian homes use a lot of energy. The home and building sectors account for 13% of Canada’s greenhouse gas emissions. This figure increases to 18% when electricity is used for cooling, lighting, and household appliances. To this end, the government has pledged to spend $2,6 billion over seven years starting from 2020—2021 to support homeowners in improving the energy efficiency of their homes. Up to 700,000 grants of up to $5,000 are also being provided to support households make energy-efficient changes to their homes.

The transition to the CE brings tremendous economic benefits. According to Efficiency Canada, in 2018, more than 436,000 jobs related to energy efficiency were created yearly, at an annual growth rate projection of 8% year on year [56]. Between 2017 and 2030, energy efficiency measures would raise British Columbia’s average yearly GDP by $3,8 billion and create an average annual of 18,300 jobs. In Saskatchewan, an average of 3,400 jobs will be created annually, and GDP will increase by an average of $800 million per year. In Ontario, GDP will increase by an average of $12,5 billion, with 52,900 jobs created annually, and in PEI, GDP will rise by $200 million, with 1,500 new jobs.

A reduction in the volume going into landfills reduces waste management and storage costs, thereby improving economic benefits. For instance, closed-loop recycling cycles at mines enable the reutilization of by-products and reduce environmental costs, thus giving the economy more resilience.

Some accelerators help Canada move toward the CE. Legal actions like adopting laws that promote recycling. In 2016, the national program framework was built, which included detailed measures to reduce carbon dioxide emissions, and these are foreseen to be reduced by 227 million tons until the year 2030. Investments by public and private sectors in recycling infrastructure and innovative technologies facilitate this acceleration of changes. It is expected that in the coming years there will be an increase in the number of jobs in the clean economy in Canada (fig.14).