Полная версия:

How to Build a Car

It’s not a criticism. Far from it. If I could go back to design at any point in the sport’s history, it would be then, because if you look at the cars on the grid from the early to late 1970s, they all looked very different to each other. The rulebook then was small; they had a huge amount of freedom, but relatively little understanding of the end product, purely because they didn’t have the research tools that we benefit from today; they were only just waking up to the possibilities of wind tunnels and the kind of simulation tools we now use routinely.

But they were pioneers. They’d be trying new suspension geometries, ‘anti-dive’, ‘anti-lift’ or adaptable suspension that ended up flexing like bits of chocolate. Great ideas that somebody came up with in the shower or standing at their drawing board staring off into space. All of them released to great fanfare and acclaim. Most of them abandoned almost immediately. Giddy times.

Of all these early pioneers, the most buccaneering was Colin Chapman, founder and boss at Lotus and the closest thing I have to a design hero.

Chapman was one of the few who did in fact have aeronautical training, which he used to great effect. He had a tendency, though, to start afresh rather than build on past success, so having won the championship with a car powered by a Cosworth DFV engine in 1968 – the first car to feature that engine – Colin then decided to invest heavily in four-wheel drive, a lame duck of an idea that resulted in cars that were way too heavy to be competitive.

Another blind alley in the form of an inefficient gas turbine car meant that by 1970 Lotus were still racing the same car that had won the 1968 championship and were struggling to catch up. The Lotus 72 of mid-1970 was a gem that held them high through to 1972, followed by a further series of blind alleys. It wasn’t until the Lotus 78, the ground-effect car, that they became competitive again. And though they didn’t win the championship that year, the following year’s car, the Lotus 79, dominated 1978.

After that, however, Lotus returned to blind alleys. When Gordon Murray of Brabham introduced pullrod suspension to replace the old rocker system, and John Barnard at McLaren replied with a pushrod set-up – both of which helped cars cope with the huge loads generated by downforce – the Lotus answer was to develop a chassis with a separate aerodynamic shell linked directly to the wheels, so it transmitted all its downforce straight to the wheels, not through the suspension. It didn’t really work and, to add insult to injury, it was banned.

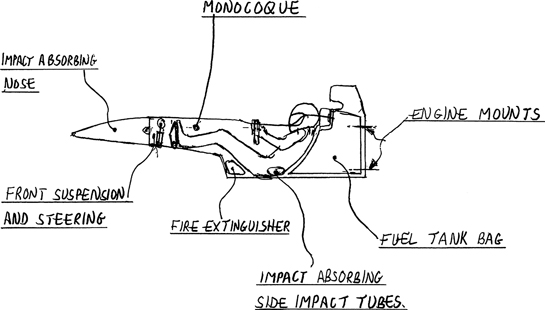

Figure 4: The monocoque with its many components.

Personally, I would have been intrigued to meet Chapman. He was a fascinating character, a real innovator. It was he who espoused the idea that high power was less important than good handling. He had a talent for applying advances made in disciplines other than F1. So, for example, he’s often credited as being the first to introduce monocoque construction, where instead of constructing a chassis from steel tubes, you make it out of sheets of aluminium. It was a revolution in Formula One, but the Jaguar D-type of 1954 was the car that had really introduced this construction technique to motor racing. Same with bolting the engine straight to the chassis instead of to a sub-frame.

Sadly, the ground-effect car was Chapman’s last hurrah. Not long afterwards, he teamed up with John DeLorean to design the DeLorean, the Back to the Future car, after which there were allegations of murky dealings, which were followed soon afterwards by an upcoming court case and an untimely fatal heart attack in 1982, when Chapman was aged just 54.

Mario Andretti, the driver of the ground-effect car during that championship-winning season, always maintained that Chapman had faked his own death and fled to Brazil in order to escape trial, a claim that would be absurd if it were anybody else but Chapman.

Meanwhile, back at Southampton University, I noticed that even though all the Formula One teams had cottoned on to the benefits of ground effect (marking the end of the era of crazy ideas in the shower and the beginning of a time when the design of cars began to converge into a generic shape), sports cars were lagging behind.

So for my final-year project I chose to study ‘ground-effect aerodynamics as applied to a sports car’.

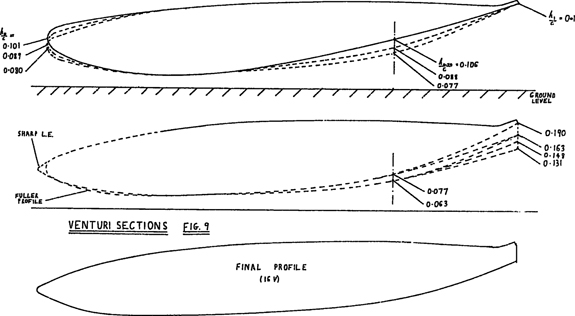

I set to work. I made a wing out of aluminium. This would go on the underside of my car, which was to be a road-going sports model. I tested it on its own using pressure taps to develop the shape in a small wind tunnel until I was happy with it. I designed a one-quarter-scale model of the car, which incorporated the underside wing shape, made it, and then took that into the main 7ft × 5ft tunnel.

It’s fair to say, I’ve spent a good part of my life in wind tunnels, understandably so when you consider the huge benefit they offer to someone who designs performance cars for a living. A wind tunnel allows you to measure how much downforce and drag you’re generating, and how that downforce is distributed; how much is on the front axle, how much is on the rear. You can also measure side, yaw and roll forces. With various caveats, you can measure the full aerodynamic performance of a car without actually having to build the car itself.

Figure 5: Technical drawing from my university project, illustrating 2D sections of the underside wing shape (venturi).

Truth be told, I put more work into my project than I should have done for what, after all, counted for just 25 per cent of the final degree. But I loved doing it. It felt like going back to my roots, like being back at home during the summer holidays, only now I had a wind tunnel in which to test my sketches and the models I built from them. It was my school-summer-holiday upbringing applied at university.

The finished article certainly created a lot of downforce. What I’d done was to make use of the Lotus innovation by featuring a skirt that sealed to the ground and stopped the leakage of air, coupled to a full-width underwing, but at the same time I had proposed a mechanical package that would allow this aerodynamic shape. True, as a road car it wouldn’t have been terribly practical due to the fact that in order to deal with the downforce the car’s suspension would have had to be very stiff and therefore very uncomfortable. So I proposed a variable geometry spring system linked to car speed – what would later become known as active suspension. It was, as far as I know, the first properly researched study of ground-effect aerodynamics applied to a sports car.

More importantly, as well as leaving me with a good understanding of ground-effect aerodynamics, it gave me something I could show to prospective employers. And it contributed to my achieving a first-class honours degree, the very idea of which would have caused me to utter a four-letter expletive had it been suggested at Christmas of my first year.

CHAPTER 7

While at university I’d written to Gordon Murray, chief designer at Brabham, telling him how highly I thought of him, as well as outlining an idea I’d had for a suspension system that kept the camber of the wheels upright in cornering.

I loved Brabham. I’d got to know a few of their guys from using the Southampton wind tunnel, and I thought the idea was a good one. Moreover, since Brabham was the only team apart from Ferrari to use a transverse gearbox, which was more suitable for my suspension system idea than a conventional longitudinal gearbox, they were the perfect recipients for it.

With hindsight, the concept wasn’t so great. It would have been difficult to get it stiff enough without compromising the structure of the chassis. Gordon, who all these years later still remembers me writing to him, replied in characteristically polite terms, letting me down gently but offering me encouragement for the future. Along with March, where Ian Reed had ended up, Brabham had gone to the top of my hit list when it came to looking for a job post-graduation.

But when I enquired, neither of them had an opening. Nor did any of the other dozen or so teams in both Formula One and Two that I subsequently wrote to – a large and costly carpet-bombing operation that involved sending photocopied extracts from my university project in order to convince them of my brilliance.

Roughly half simply ignored me. Most of the rest replied with the ‘Catch 22’ answer that they wanted someone with experience. Tyrell Racing offered me an interview, and subsequently a job subject to sponsorship. But the sponsorship didn’t come through so the job didn’t either, although they were impressed with the extract.

As were Tiga, a Formula Two team out of Caversham near Reading. Theirs was a nice, tidy workshop run by a couple of Aussies, Tim Schenken and Howden Ganley. During my interview with Schenken, Ganley returned from a trip to Reading library laden down with books, apparently hoping to understand how to design and build his own wind tunnel. I admired his can-do spirit, but building a wind tunnel after a visit to Reading library felt somewhat optimistic.

Still, they were a likeable pair, and they too offered me a job subject to sponsorship. Which never arrived, meaning neither did the job.

In desperation I went for an interview at British Leyland, an all-day thing where I joined a bunch of other applicants. The worker in charge of my group told us he’d spent the previous year performing stress-analysis tests on the tailgate of a Morris Ital estate car, and I thought to myself, I don’t think I can do that – spend a whole year performing stress-analysis tests on a tailgate.

We went for lunch and, gazing out of the canteen windows, we could see a car shrouded in what looked like black bin liners doing circuits of a test track. There was great excitement among the other candidates. Could it be …? Was this the exciting new British Leyland car? The Metro. That confirmed my worry: I definitely cannot do this job and remain sane!

Way more encouraging was a job offer from Lotus, except that, typical of my luck at the time, it wasn’t Lotus the racing team but Lotus road cars. And while I had personal history with Lotus road cars, and there was always a chance I might be able to attract attention from the team, their big hit of the time was the Lotus Esprit, which I thought was an ugly, awful thing enjoying unwarranted popularity thanks to its appearance in The Spy Who Loved Me.

Arriving for an interview I was struck by the fact that the factory was an utter pigsty. As well as the Esprit, bits of which I saw were made of thick, poorly contoured fibreglass, they were deep into research and design for the DeLorean, which had all the hallmarks of the design monstrosity it would later prove to be.

Still, it was a job offer, the best I had, and I was about to accept – on the verge of doing so, in fact – when the phone rang.

At the other end was Harvey Postlethwaite, technical director at Fittipaldi Automotive and already on the road to becoming a design legend, with a later stint at Ferrari sealing the deal in that regard.

Harvey liked the project sample I’d sent. Would I come for an interview?

A day or so later I rode into the Fittipaldi HQ at Reading, which turned out to be a small factory unit, a couple of Portacabin offices and a herringbone car park. Sitting in reception, still in my biking leathers, I was greeted by Harvey, hair a mess, big grin on his face.

‘You’re a biker,’ he said, delighted by the sight of my leathers. ‘What have you got?’

‘Ducati 900SS,’ I told him.

‘Fantastic,’ he said, ‘mine’s a Moto Guzzi Le Mans.’

This was a time when one of the hot points of discussion in the bike magazines was about which was the superior Italian bike, Moto Guzzi or Ducati. Harvey was eager for first-hand experience and asked if he could take my Ducati out for a spin.

‘Sure,’ I said, and stood in the car park for what felt like an age as he took my bike for a run God knows where, returning and taking off his helmet to reveal even messier hair and an even bigger grin.

‘Right,’ he said, ‘when can you start?’

As interviews go, it beat sitting in the British Leyland canteen.

CHAPTER 8

I began at Fittipaldi with the title of ‘junior aerodynamicist’, but because they didn’t have any other aerodynamicists, I was senior aerodynamicist as well.

It was that sort of place, teeming with early 1980s chaos and run on a diet of cigarettes, coffee and beige polyester. A team of around 35 was split between the factory and Portacabin offices, but although it was a respectable size for the time – a bit smaller than Lotus but not by much – its problem was that there were more chiefs than Indians thanks to the fact that it was comprised of two teams that had merged: the original Fittipaldi Automotive, founded by driver-brothers Wilson and Emerson, and Wolf Racing, whose main driver was Keke Rosberg (father of Nico).

Parachuted into the middle of the post-merger manoeuvring, I managed to steer clear of the various office politics, stepped-on toes and egos that had been bruised by the fusion. Being junior meant I could move easily between the Portacabins in the gravel car park and the factory, where on Fridays, after the traditional lunchtime in the pub, workers sat down to an afternoon of hard-core pornography. I didn’t care. I was just happy to be in Formula One at last.

One day, the atmosphere in the Portacabins was more than usually fevered thanks to the expected arrival of Emerson.

Never being one to idolise drivers, my own fires were under control, but I was intrigued because I hadn’t yet crossed paths with the great man, his visits to base camp being somewhat infrequent.

Then, as now, my office overlooked the car park, and as the morning wore on I noticed that somebody had left a chassis stand in Emerson’s parking space. As I say, he hardly ever came in, so whoever put it there probably thought it was a safe place. Except on this particular occasion it wasn’t, because Emerson came haring into the car park, typical racing driver, going way too fast and coming in blind, sideways into his parking spot in a spray of gravel … slap-bang into the chassis stand.

It would have been a pretty impressive bit of driving if not for the crash at the end of it. The chassis stand went flying through the hedge, having stoved in the front of Emerson’s Rover – one of those awful wedge-shaped Rovers, only now it had steam rising from where the chassis stand had burst the radiator.

As I stood watching Emerson emerge, gesticulating wildly and swearing loudly in Portuguese, and saw everybody run from the offices to witness the commotion, I remember thinking that they were all so human. Even Emerson, this hugely respected driver, was just as fallible as the rest of us.

CHAPTER 9

In 1981, the skirts that Lotus had introduced for their ground-effect car were lifted. New FIA regulations insisted they be at least 6cm off the ground, and could no longer slide up and down, which of course would hugely reduce their effectiveness since they’d no longer be sealed to the track.

In response, teams fitted rubber skirts to the cars, but they didn’t work nearly as well because they flexed in a poorly controlled way and wore out – which is something that rubber does when it slides along the ground.

Those 1981 cars were really 1980 cars with these much less effective skirts. It was my first taste of a major regulation change, and I felt the aero needed to be fundamentally redesigned to re-optimise to this new limitation.

My idea was simple: to raise the underwing and make it longer, so that the leakage under the rubber skirts would be, as a percentage of the overall flow under the car, smaller. It was a sound principle, but to accommodate it meant significantly redesigning the rear suspension.

Straightaway, I was into something I find fascinating: the integration of mechanical and aerodynamic design (something I had tried to bear in mind with my project at Southampton).

We started to develop it through 1981 with the intention of it being the car for 1982. Once a month we’d load a Vauxhall Chevette van with the model and any other tools we needed, and then Pip, our fabricator, and I would drive to the wind tunnel at Imperial College in Kensington.

They were early morning starts, the whole operation conducted in a hurry. On one particularly icy morning I span the Chevette across the slip road onto the M4, clouting the barrier on the outside. Together, we pulled the wheel arch back out to stop it rubbing on the wheel, clambered shivering back inside and kept on going.

Once at the tunnel, we’d do a run on the model, measure how much downforce and drag it produced, and then make alterations to it – for example, by changing the front wing altogether, varying the angle of the existing wing, or doing the same to the sidepods or the diffuser.

Nowadays, there’s almost no adlibbing on the model; everything on it is a pre-manufactured part and test schedules are followed because that’s the best way to be efficient. Back then, though, we’d come armed with all sorts of bits and pieces, with Pip and the model-maker on hand to make alterations, and me recording the results and making calls on what to do next. We had limited resources and there was a lot of improvisation, but if we had an interesting direction we’d make a part on the spot, stick it on and try it.

Our numbers were good, a big improvement on the 1981 car. Bearing in mind we had no idea what other teams were getting from their own cars – you rarely do, of course – we were quietly confident that we had a decent design on our hands. Joining Williams years later, I compared notes with Patrick Head, and based on what he told me about the 1982 Williams car, ours would have been very competitive.

But it’s by no means an easy feat to translate wind tunnel results to the finished article. You need sufficient resources for engineering, detailed design and manufacturing, and in that respect Williams always had a head start. But on paper at least, our Fittipaldi was championship material. We could have been a contender.

The ifs and buts of motor racing. In the event, the rug was pulled …

I’d started at Fittipaldi in August 1980, but by Christmas 1981 it became apparent that there was something rotten in the state of Reading. When I first began, the team was sponsored by Skol beer, and there was, if you will excuse the pun, a fair bit of money swilling about for development and a can-do atmosphere. At the end of that year Skol pulled out, to be replaced by Avis for 1981, meaning much less finance available.

Work continued on the 1982 car. We’d begun designing a rear suspension to complement the aerodynamics – to the point that drawings were ready to go off for manufacturing the components – when suddenly the whole thing was stopped because there was no money left to build the car. We were told we would have to use the 1981 car in 1982.

Staff began leaving. Harvey joined Ferrari. One of the team managers, Peter Warr, left for Lotus and the other, Peter Mackintosh, joined March. That positive, can-do attitude evaporated.

It was with a heavy heart that I found myself looking for something new.

CHAPTER 10

In those days, every motor racing team effectively had three engineering disciplines: the design and aerodynamics offices, and race engineering, though the race engineers would be doubling up with working in the design office during the week.

Since then, the industry has mushroomed, and nobody crosses from one department to another. You’ll have, let’s say, 90 people in aerodynamics, another 70 in the design office, and perhaps 30 in race engineering and simulation, the latter being a relatively new area.

Me, I’m known chiefly as an aerodynamicist, but that’s a product of the fact that aerodynamics is the biggest single performance differentiator. Therefore, I tend to spend most of my time looking at aerodynamics, with the mechanical layout a close second, in order to make sure the two complement one another in a package. In fact, my sole interest lies in improving the ability of the car to score points, and what helps me do that is my experience across the disciplines.

Which brings me back to early 1982, when of the three key areas – aerodynamics, mechanical design and race engineering – I only had experience of the first. With Fittipaldi I had been loosely involved in the design of the rear suspension for the axed 1982 car, but not in the detail. I’d been to the track a grand total of once, and that was for a cold test at Donington where I just stood and watched the car do a few shakedown laps. I’d never even worn a set of headphones.

At its simplest level, what a race engineer does is work with the driver to get as much performance from the car as he can. It incorporates basics like issuing instructions to the mechanics on how much fuel to put in and which set of tyres to fit for each outing, as well as ensuring that the set-up is correct depending on the conditions: the weather, of course, but also the track.

The tools the race engineer has at his disposal are what we call the set-up parameters: that’s the front and rear spring rates, the roll bar stiffness, the damper settings, the wing settings, the ride-heights, the camber, caster and toe-in or toe-out of the wheels, gear ratios, etc. It’s all about trying to find the right set-up for the car, the driver – each driver has his own race engineer – and the circuit.

What attracted me to race engineering, besides the chance to learn something new, was the opportunity to combine that with being a designer and an aerodynamicist. I could influence the development of a car based on first-hand knowledge of its performance at the track.

So say, for example, the driver was complaining of a handling problem. In the first instance I could talk to him in a race-engineering capacity and perhaps reduce the problem through the set-up of the car. But with an engineer’s eyes I could also hope to understand whether that problem was inherent to the mechanical design or the aerodynamic characteristics of the car. My understanding of the car would be complete.

So when Peter Mackintosh, having left Fittipaldi to take charge of the March Formula Two team, offered me a job, and that job was the chance to work as a race engineer at the weekends, then in the drawing office during the week as a draughtsman, I was sorely tempted, and probably would have signed immediately if not for the fact that Peter Warr offered me a post at Lotus as an aerodynamicist.

Now I had some real thinking to do. Should I stay in Formula One and go to Lotus, ‘my’ team? Or should I take the opportunity to learn the two missing disciplines in my CV at March, albeit with a drop to the lower categories?

In truth there wasn’t a huge amount of deciding to be done. You might say I’m lacking in sentimentality, but I prefer to think of it as taking a clear-eyed view of the future. I really wanted to add that race-engineering-and-design-draughtsman string to my bow. I chose March.

I began work. Feeling awfully wet behind the ears, and only too aware that I’d be race engineering drivers a few years older than I was, I grew a beard. Peter Mackintosh, the team manager, with no engineering background but lots of experience, was race engineering Corrado Fabi, while Ralph Bellamy, the Aussie veteran engineer who designed the Formula Two car, engineered Johnny Cecotto. I was given the third car, driven by Christian Danner.

My first race of the Formula Two season was at Silverstone, on 21 March 1982. And it was straight in at the deep end, having joined too late to attend any of the pre-season tests. It was raining, so I saw to it that the wet tyres were on and correctly pressured, and I made sure that there was fuel in the car. Simple stuff, I know, but I wanted to at least get through the weekend having got the basics right.